The Future of Chemical Manufacturing: A Look at Automated Systems and Robotics

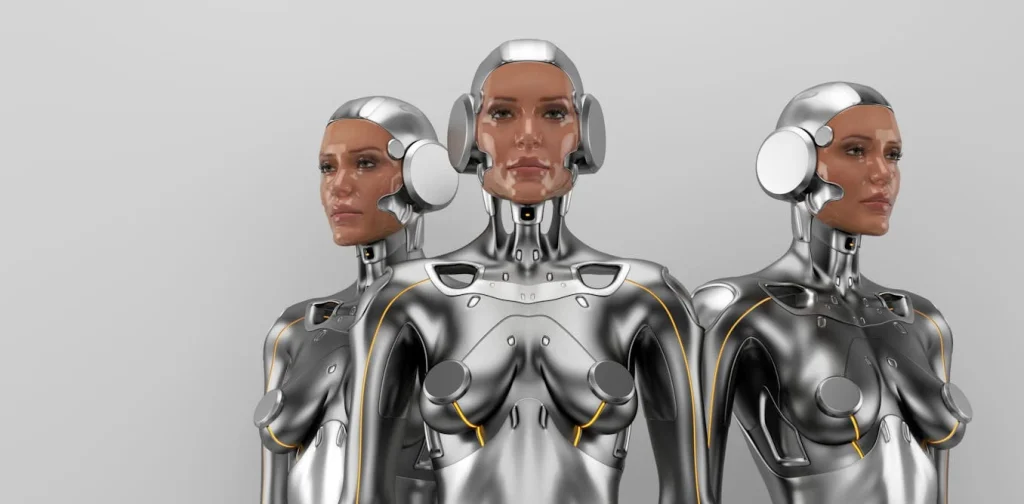

The world of chemical manufacturing is constantly evolving, and with the rise of new technologies, there is a growing interest in the use of automated systems and robotics in this industry. These advancements have the potential to revolutionize the way chemicals are produced, making the process more efficient, cost-effective, and safer for workers. In this blog post, we will explore the future of chemical manufacturing and how automated systems and robotics are playing a crucial role in shaping it.

Automated systems and robotics have been making their way into various industries for years, and chemical manufacturing is no exception. These systems can handle a wide range of tasks, from mixing and measuring chemicals to packaging and labeling products. By automating these processes, companies can increase productivity, reduce human error, and improve overall efficiency.

One of the key benefits of using automated systems in chemical manufacturing is the increased safety for workers. Chemical production can be a hazardous process, with exposure to toxic substances and potential accidents. By implementing automated systems, workers can be removed from potentially dangerous situations, reducing the risk of injuries and long-term health effects. This is especially important in light of the recent COVID-19 pandemic, which has highlighted the need for social distancing and reducing human contact in manufacturing facilities.

In addition to safety, automated systems and robotics also offer significant cost savings for chemical manufacturers. These systems can work around the clock without breaks or the need for human supervision, leading to increased output and lower labor costs. They also have a higher level of precision, resulting in less waste and more consistent product quality. This can lead to cost savings in the long run, as fewer resources are needed for production and there is less risk of product recalls due to human error.

The Future of Chemical Manufacturing: A Look at Automated Systems and Robotics

The use of robotics in chemical manufacturing is also expected to improve sustainability efforts. With the ability to accurately measure and control the amount of chemicals used in production, there is less waste and a decreased environmental impact. Additionally, automated systems can help identify and address potential safety or environmental hazards in real-time, preventing long-term damage and costly clean-up efforts.

One example of the implementation of automated systems in chemical manufacturing is the partnership between BASF and the robotics company ABB. BASF, a leading chemical producer, has been working with ABB to develop a fully automated chemical production plant in Shanghai, China. This plant will utilize advanced robotics and digital technologies to produce a range of chemicals, including polyurethane and engineering plastics. This partnership is expected to increase efficiency, reduce costs, and improve safety for workers.

Another current event that highlights the use of automated systems in chemical manufacturing is the recent announcement by DuPont that they will be investing $28 million in their chemical production facility in Richmond, Virginia. The company plans to use advanced automation and digital technologies to improve their production processes and increase efficiency. The investment is expected to create 60 new jobs and improve the company’s competitiveness in the global market.

The future of chemical manufacturing is undoubtedly tied to the advancements in automated systems and robotics. As technology continues to evolve, we can expect even more innovative solutions to be implemented in chemical production processes. This will not only benefit companies in terms of safety, cost, and sustainability but also have a positive impact on the environment and the communities in which these facilities operate.

In summary, the use of automated systems and robotics in chemical manufacturing is rapidly expanding, and for good reason. These technologies offer numerous benefits, including increased safety, cost savings, and improved efficiency and sustainability. With the recent advancements and investments in this area, it is clear that this is the future of chemical manufacturing, and we can expect to see even more innovative solutions in the years to come.